Time:

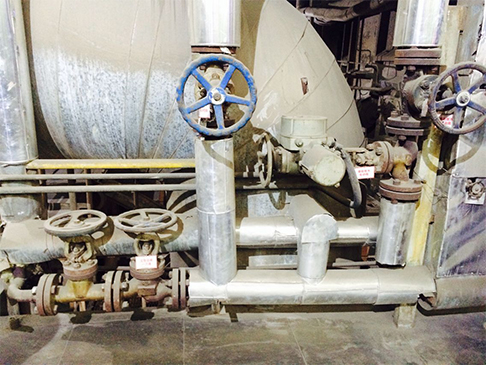

A steam valve is a valve used to control the flow of steam, which plays a vital role in various industrial applications. The following are some common steam valves:

Globe Valve: Globe valves are one of the most common steam valves. They control the flow of steam by raising and lowering the valve cover. When the valve cover is raised, steam can flow freely through the valve; when the valve cover is closed, the valve can completely cut off the flow of steam.

Gate valve: The gate valve consists of a gate that moves up and down and two sealing seats. They control the flow of steam with rams that move up and down. When the gate is raised, steam can flow through the gate valve; when the gate is lowered, the gate valve can completely cut off the flow of steam.

Regulating Valve: Regulating valves are used to precisely regulate the flow and pressure of steam. They are usually operated by manual or automatic controls. By adjusting the opening of the valve, precise control of the steam flow can be achieved to meet the requirements of different processes and equipment.

Safety Valve: A safety valve is a valve used to protect a system from excessive pressure. They are usually set on steam pipelines or equipment. When the steam pressure exceeds the set value, the safety valve will automatically open and release the overpressured steam to protect the safe operation of the system.

Steam Traps: Steam traps are used to remove condensate from steam piping. During steam transfer, the moisture in the steam condenses into water droplets, forming condensate. Steam traps automatically remove condensate, preventing it from accumulating and interfering with the normal flow of steam.

Plug valve: The plug valve consists of a disc-shaped valve core and valve seat, and the flow of steam is controlled by rotating the valve core. The plug valve is suitable for high temperature and high pressure steam control, and has good sealing performance and regulating performance.

Ball valve: The ball valve consists of a ball and two sealing seats, and the flow of steam is controlled by rotating the ball. Ball valves usually have fast switching and good sealing performance, and are suitable for occasions that require frequent switching.

The above are several common steam valves, which are widely used in different industrial fields to control the flow, pressure and temperature of steam. The selection and use of steam valves are very important to ensure the safety, efficiency and stability of industrial production.

Relative News

What are the media used for knife gate valves? Knife gate valves, with their unique design and performance, are widely used in many fields and are suitable for a variety of different media.

Knife gate valves are widely used in industrial production and daily life. Choosing the appropriate type of knife gate valve requires comprehensive consideration of multiple key factors.

Submit Request