Intro

POPU Valve: PTFE Lined Y Strainer

PTFE lined Y strainer is a filter with PTFE lining layer, which has high chemical stability and is suitable for highly corrosive chemical media.

PTFE lined Y strainer is designed for pipeline filtration of various highly corrosive media, and is widely used in petroleum, chemical, dyeing, pesticide, acid and alkali industries.

| Body | Strainer Screen | Gaskets |

| Material | WCB+F46 | F46 | PTFE |

| Optional | WCB/CF3M/CF8/ CF8M | F4/F46/PFA | FEP/PFA/PTFE |

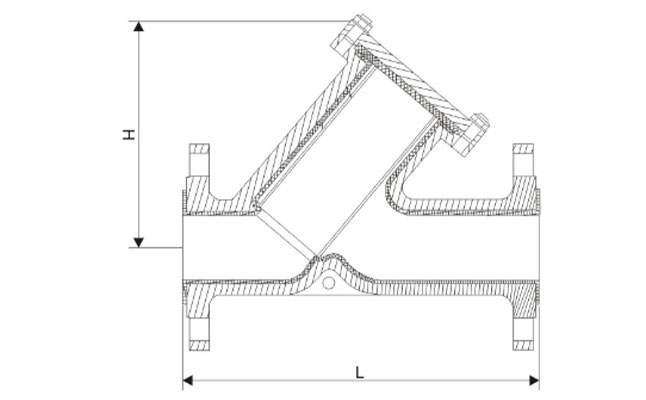

Parameters

| DN | NPS | L | H | ΦD | ΦK | n-Φd |

| 25 | 1'' | 165 | 115 | 115 | 85 | 4-14 |

| 32 | 1 1/4'' | 185 | 115 | 140 | 100 | 4-18 |

| 40 | 1 1/2'' | 200 | 145 | 150 | 110 | 4-18 |

| 50 | 2'' | 230 | 165 | 165 | 125 | 4-18 |

| 65 | 2 1/2'' | 295 | 175 | 185 | 145 | 8-18 |

| 80 | 3'' | 315 | 205 | 200 | 160 | 8-18 |

| 100 | 4'' | 355 | 230 | 220 | 180 | 8-18 |

| 125 | 5'' | 405 | 285 | 250 | 210 | 8-18 |

| 150 | 6'' | 480 | 315 | 285 | 240 | 8-22 |

| 200 | 8'' | 605 | 400 | 340 | 295 | 12-22 |

| 250 | 10'' | 680 | 430 | 405 | 355 | 12-26 |

| 300 | 12'' | 780 | 470 | 460 | 410 | 12-26 |

Advantages

1. The filter adopts the form of full warp and streamlined design to reduce the fluid resistance coefficient of the filter. The size of the filter diameter and length is increased, which increases the effective filtration area of the filter screen and reduces the pressure loss.

2. The middle cavity is enlarged, and the circulation area between the filter screen and the inner wall of the valve is greater than half of the flow channel area, which effectively improves the utilization rate of the mesh hole at the back of the filter screen and reduces the pressure loss.

3. The position of the sewage hole is designed at the low end of the valve cover to make the sewage discharge more thorough, and at the same time increase the size of the sewage hole to improve the sewage discharge efficiency.

4. The electrostatic coating of powder epoxy resin inside and outside the valve body can effectively prevent corrosion and rust caused by the contact between the valve body and the medium while improving the adhesion, and improve the service life of the product by 1.5 times and the spraying thickness of more than 250um.

5. POPU has a professional production, sales, R&D and after-sales team to ensure that the products delivered to customers are 100% qualified.

6. POPU products provide 24-month quality assurance.