Intro

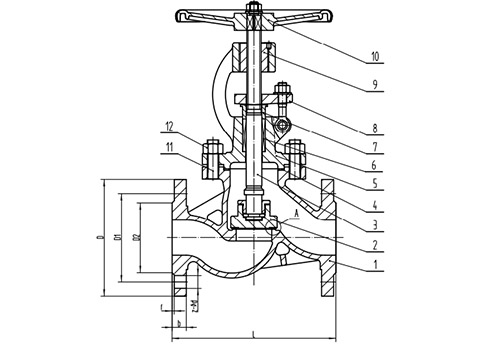

POPU Valve: Stainless Steel Globe Valve

The stem axis of the globe valve is perpendicular to the sealing surface of the valve seat, the stem opening or closing stroke is relatively short, and it has a very reliable cut-off action, making this valve very suitable for the cutting or adjustment of the medium and throttling.

Stainless steel globe valve has relatively high material requirements for the valve body, and generally has 304, 316 and other material options. It is suitable for pipelines with various corrosive media, with good corrosion resistance and sufficient strength.

| Name | Body | Seat | Disc | Stem | Actuator |

| Material | 304 | 304 | 304 | 304 | Hand Wheel |

| Optional | 304/316 | SS/Alloy Steel | 304/316 | 2Cr13/304/316 | Worm gear/Electric/Pneumatic |

Parameters

| Size | PN16 | 150LB |

| DN | NPS | L | D | DI | Z-Φd | L | D | D1 | Z-Φd |

| 50 | 2'' | 230 | 160 | 125 | 4-18 | 203 | 152 | 120.5 | 4-19 |

| 65 | 2 1/2'' | 290 | 180 | 145 | 4-18 | 216 | 178 | 139.5 | 4-19 |

| 80 | 3'' | 310 | 195 | 160 | 8-18 | 241 | 190 | 152.5 | 4-19 |

| 100 | 4'' | 350 | 215 | 180 | 8-18 | 292 | 229 | 190.5 | 8-19 |

| 125 | 5'' | 400 | 245 | 210 | 8-18 | 356 | 254 | 216 | 8-22 |

| 150 | 6'' | 480 | 280 | 240 | 8-22 | 406 | 279 | 241.5 | 8-22 |

| 200 | 8'' | 600 | 335 | 295 | 12-22 | 495 | 343 | 298.5 | 8-22 |

| 250 | 10'' | 650 | 405 | 355 | 12-26 | 622 | 406 | 362 | 12-25 |

| 300 | 12'' | 750 | 460 | 410 | 12-26 | 698 | 483 | 432 | 12-25 |

Advantages

1. Valve body casting precision, materials in line with standards, beautiful appearance, no sand eyes, material inspection guarantee.

2. Heavy type body,the inner part is processed by CNC lathe. Twice polish will ensure sealing performance.

3. An inverted seal is used between the contact surface of the cover plate and the valve stem to avoid leakage.

4. Each valve body is surface pickling and passivated treatment, so that the casting appearance is uniform silver and bright color, maintain metallic luster, improve corrosion resistance

5. Each valve leaves the factory in accordance with the national standard for shell, sealing double-layer pressure testing.

6. From the production of each part to the finished product packaging and delivery, strict quality control is carried out for each link.

7. POPU has a professional production, sales, R&D and after-sales team to ensure that the products delivered to customers are 100% qualified.

8. POPU products provide 24-month quality assurance.