Intro

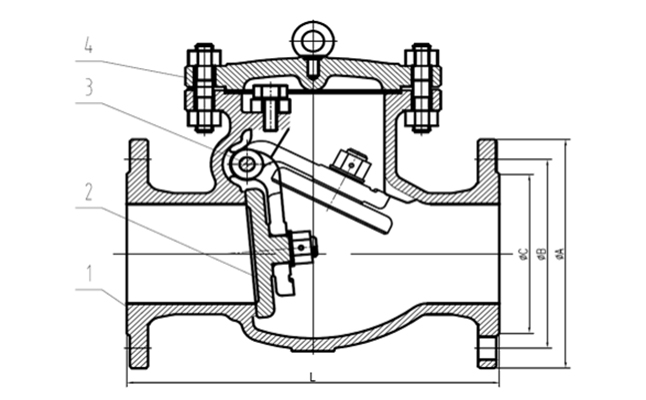

POPU Valve: Stainless Steel Swing Check Valve

Stainless steel swing check valve disc disc shape, around the seat channel of the axis of rotation movement, because the valve channel into a streamlined shape, flow resistance than lifting check valve is smaller, suitable for low flow rate and flow infrequent changes in large diameter occasions, but not suitable for pulsating flow, its sealing performance is not as good as lifting type.

Parameters

| DN | NPS | PN16~PN40 | PN16 |

| L | ΦA | ΦB | ΦC |

| 40 | 1 1/2'' | 200 | 150 | 110 | 88 |

| 50 | 2'' | 230 | 165 | 125 | 102 |

| 65 | 2 1/2'' | 290 | 185 | 145 | 122 |

| 80 | 3'' | 310 | 200 | 160 | 138 |

| 100 | 4'' | 350 | 220 | 180 | 158 |

| 125 | 5'' | 400 | 250 | 210 | 188 |

| 150 | 6'' | 480 | 285 | 240 | 212 |

| 200 | 8'' | 550 | 340 | 295 | 268 |

| 250 | 10'' | 650 | 405 | 355 | 320 |

| 300 | 12'' | 750 | 460 | 410 | 378 |

| 350 | 14'' | 850 | 520 | 470 | 438 |

| 400 | 16'' | 950 | 580 | 525 | 490 |

| 500 | 20'' | 1150 | 715 | 650 | 610 |

Advantages

1. Valve body casting precision, materials in line with standards, beautiful appearance, no sand eyes, material inspection guarantee.

2. The inner part is processed by CNC lathe. Twice polish will ensure sealing performance.

3. Products can be used in a variety of piping flange and flange standard and flange seal type, to meet a variety of engineering needs and user requirements.

4. Valve body variety, gasket can be based on actual conditions or user requirements reasonable matching, can be applied to a variety of pressure, temperature and medium conditions.

5. Each valve leaves the factory in accordance with the national standard for shell, sealing double-layer pressure testing

6. From the production of each part to the finished product packaging and delivery, strict quality control is carried out for each link.

7. POPU products provide 24-month quality assurance.