Intro

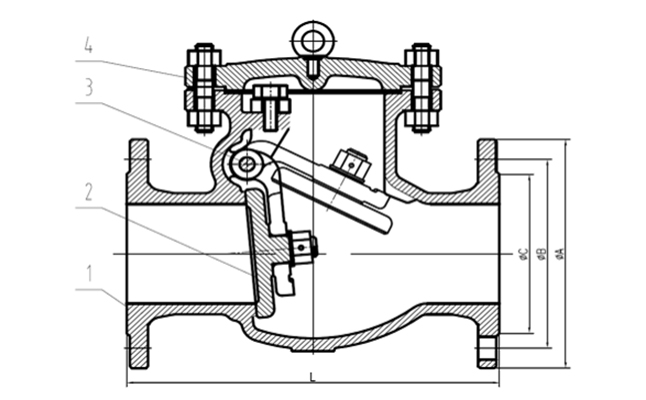

POPU Valve: WCB Swing Check Valve

H44H cast steel swing check valve is suitable for large diameter occasions with low flow rate and infrequent flow changes, but it is not suitable for pulsating flow, and its sealing performance is not as good as that of lifting type.

The purpose of the swing check valve is to prevent the hydraulic impact when the medium stops flowing or backflows.

Parameters

| DN | NPS | PN16~PN40 | PN16 |

| L | ΦA | ΦB | ΦC |

| 50 | 2'' | 230 | 165 | 125 | 102 |

| 65 | 2 1/2'' | 290 | 185 | 145 | 122 |

| 80 | 3'' | 310 | 200 | 160 | 138 |

| 100 | 4'' | 350 | 220 | 180 | 158 |

| 125 | 5'' | 400 | 250 | 210 | 188 |

| 150 | 6'' | 480 | 285 | 240 | 212 |

| 200 | 8'' | 550 | 340 | 295 | 268 |

| 250 | 10'' | 650 | 405 | 355 | 320 |

| 300 | 12'' | 750 | 460 | 410 | 378 |

| 350 | 14'' | 850 | 520 | 470 | 438 |

| 400 | 16'' | 950 | 580 | 525 | 490 |

| 500 | 20'' | 1150 | 715 | 650 | 610 |

Advantages

1. Valve body casting precision, the material WCB meets the standard, beautiful appearance, no sand eyes, material inspection guarantee.

2. The inner part is processed by CNC lathe. Twice polish will ensure sealing performance.

3. The weight of the same caliber is heavier than the same valve.

4. Valve seat CR system + overlay welding 507 molybdenum to increase the wear resistance of the valve seat .

5. Each valve leaves the factory in accordance with the national standard for shell, sealing double-layer pressure testing

6. From the production of each part to the finished product packaging and delivery, strict quality control is carried out for each link.

7. POPU products provide 24-month quality assurance.