Time:

Cast steel valves and stainless steel valves are two valve materials commonly used in the industrial field. They have some differences in materials, performance and uses. This article will compare cast steel valves and stainless steel valves in terms of material, corrosion resistance, applicable temperature range and use.

First of all, cast steel valves are made of carbon steel and alloy steel. Carbon steel has high strength and wear resistance, while alloy steel has some alloying elements added, such as chromium, nickel, etc., to improve its corrosion resistance and oxidation resistance. Stainless steel valves are alloy materials composed of iron, chromium, nickel and other alloy elements. Due to the chromium content, stainless steel has excellent corrosion resistance and oxidation resistance.

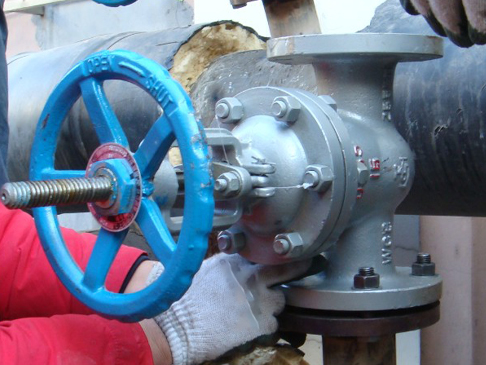

Cast steel valve

Secondly, there are differences in corrosion resistance between cast steel valves and stainless steel valves. Cast steel valves are susceptible to corrosion due to their carbon content. Therefore, the use of cast steel valves in corrosive environments may require some additional anti-corrosion measures. Because stainless steel valves contain chromium, they have good corrosion resistance and can operate stably for a long time in most corrosive media.

Third, the applicable temperature ranges of cast steel valves and stainless steel valves are also different. Since the main components of cast steel valves are carbon steel and alloy steel, they have good high temperature resistance and are suitable for applications under high temperature conditions. Due to the limitation of alloy composition, stainless steel valves have relatively weak high temperature resistance and are usually suitable for medium and low temperature conditions.

Stainless steel valve

Finally, there are differences in use between cast steel valves and stainless steel valves. Cast steel valves are usually suitable for petroleum, chemical, electric power and other industries, and are widely used in control systems of high temperature, high pressure and highly corrosive media. Stainless steel valves are mainly used in food, pharmaceutical, cosmetics and other industries, which have high requirements for hygienic performance and can meet the occasions with strict hygienic requirements for media.

To sum up, there are some differences between cast steel valves and stainless steel valves in terms of material, corrosion resistance, applicable temperature range and use. According to the specific working condition requirements, suitable valve materials can be selected to ensure the normal operation and safety performance of the system.

Relative News

What are the media used for knife gate valves? Knife gate valves, with their unique design and performance, are widely used in many fields and are suitable for a variety of different media.

Knife gate valves are widely used in industrial production and daily life. Choosing the appropriate type of knife gate valve requires comprehensive consideration of multiple key factors.

Submit Request