Intro

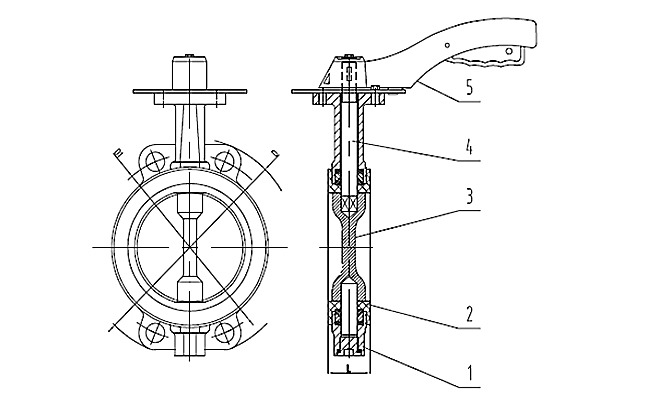

POPU Valve: PTFE Lined Handle Butterfly Valve.

The Handle is made of aluminum alloy, used for cutting valve; suitable for water supply and drainage, power generation, chemical industry and other projects.

The valve has the characteristics of strong performance, small volume, light, reliable performance, simple supporting, large circulation ability, especially suitable for viscous, granular, fiber-characteristic medium.

| Name | Body | Seat | Disc | Stem | Actuator |

| Material | WCB+PTFE | PTFE | SS304+PTFE | 2Cr13 | Handle |

| Optional | DI/CF8M/CF8/CF3/CF3M | F4/F46/PFA | WCB/CF3/ CF3M/CF8/CF8M | 45#/410/ Cr13/304/316 | Worm gear/Electric/Pneumatic |

Parameters

| DN | L | ΦD | ΦD1 | Z-Φd | f |

| 50 | 43 | 165 | 125 | 4-18 | 3 |

| 65 | 46 | 185 | 145 | 4-18 | 3 |

| 80 | 46 | 200 | 160 | 8-18 | 3 |

| 100 | 52 | 220 | 180 | 8-18 | 3 |

| 125 | 56 | 285 | 210 | 8-18 | 3 |

| 150 | 56 | 285 | 240 | 8-18 | 3 |

| 200 | 60 | 340 | 295 | 8-23 | 3 |

Advantages

1. Valve body casting precision, materials in line with standards, beautiful appearance, no sand eyes, material inspection guarantee.

2. Use domestic first-line brand PTFE raw materials. In order to ensure density and sealing, all PTFE valve seats are processed and formed after integral die-casting

3. Double sealing ring structure is adopted on both sides of the valve shaft to avoid leakage of the valve shaft.

4. From the production of each part to the finished product packaging and delivery, strict quality control is carried out for each link.

5. Each valve is subjected to double pressure testing of the housing and seal to ensure it qualifies.

6. POPU has a professional production, sales, R&D and after-sales team to ensure that the products delivered to customers are 100% qualified

7. POPU products provide 24-month quality assurance.