Intro

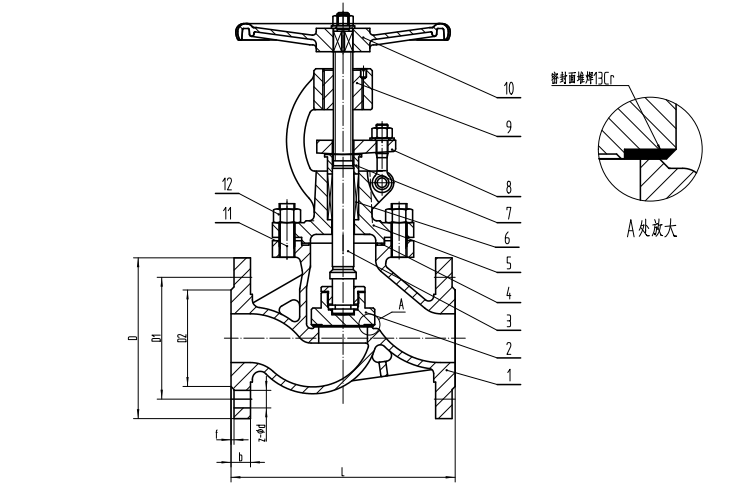

POPU Valve: WCB Globe Valve

The friction between the sealing surfaces during the opening and closing process of the globe valve is small, relatively durable, the opening height is not large, the manufacturing is easy, the maintenance is convenient, and it is not only suitable for medium and low pressure, but also suitable for high pressure.

Globe valves are ideal for shut-off or regulation and throttling. Because the stem opening or closing stroke of this type of valve is relatively short, and it has a very reliable shut-off function, and because the change of the valve seat opening is proportional to the stroke of the valve disc, it is very suitable for the adjustment of the flow.

| Name | Body | Seat | Disc | Stem | Actuator |

| Material | WCB | 13Cr | WCB+2Cr13 | 2Cr13 | Hand Wheel |

| Optional | WCB/304/316 | SS/Alloy Steel | WCB/304/316 | 45#/2Cr13/304/316 | Worm gear/Electric/Pneumatic |

Parameters

| DN | L | D | D1 | D2 | b | f | z-Φd |

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-18 |

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-18 |

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-18 |

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-18 |

| 80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-18 |

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-23 |

| 125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-25 |

| 150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-25 |

| 200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-25 |

| 250 | 650 | 425 | 370 | 332 | 36 | 3 | 12-30 |

| 300 | 750 | 485 | 430 | 390 | 40 | 4 | 16-30 |

| 350 | 850 | 550 | 490 | 448 | 44 | 4 | 16-34 |

| 400 | 950 | 610 | 550 | 505 | 48 | 4 | 16-34 |

| 450 | 1200 | 660 | 600 | 555 | 50 | 4 | 20-34 |

| 500 | 1250 | 730 | 660 | 610 | 52 | 4 | 20-41 |

Advantages

1. The valve body is all precision casting valve body, material WCB standard, fine appearance, no grit.

2. The internal parts of the CNC lathe processing, the appearance of the processing of the two times after the shot blasting, beautiful appearance.

3. The same caliber weight than other manufacturers.

4. Valve seat cr system + surfacing 507 molybdenum, increase the wear resistance of the valve seat.

5. Valve cover and valve stem contact with the inverted sealing treatment to prevent leakage.

6. Each valve leaves the factory in accordance with the national standard for shell, sealing double-layer pressure testing.All products achieve static pressure 0 leakage.

7. From the production of each part to the finished product packaging and delivery, strict quality control is carried out for each link.