Intro

POPU Valve: Concentric Wafer Butterfly Valve

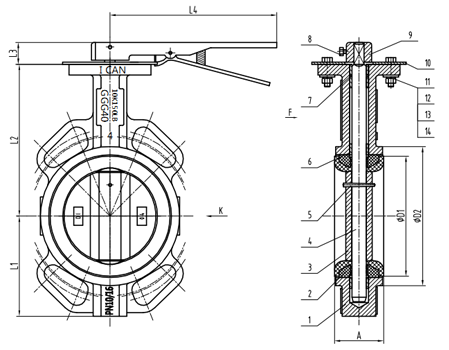

The structural characteristics of the concentric butterfly valve are that the stem axis, the butterfly plate center and the body center are in the same position, which makes the structure simple and easy to manufacture.

The channel is designed as a full bore structure, which ensures the circulation area of the valve and reduces the flow resistance when the fluid passes through the valve.

The butterfly plate adopts disc-shaped flow design, which can ensure the stress strength of the center of the butterfly plate, and also ensure that the valve can obtain a larger flow coefficient and a smaller fluid resistance coefficient.

| Name | Body | Seat | Disc | Stem | O-rings |

| Material | DI | EPDM | DI | 45#Steel | NBR |

Parameters

| DN | NPS | A | D1 | D2 | L1 | L2 | L3 | L4 | B | Top Flange |

| 50 | 2" | 45 | 73.3 | 92.3 | 75 | 129 | 24 | 220 | 9 | F05 |

| 65 | 2 1/2" | 49 | 86 | 107 | 82 | 136 | 24 | 220 | 9 | F05 |

| 80 | 3" | 49 | 100.9 | 122 | 99 | 153 | 24 | 220 | 9 | F05 |

| 100 | 4" | 55 | 132 | 153 | 110 | 167 | 24 | 250 | 11 | F07 |

| 125 | 5" | 58.5 | 156 | 179 | 125 | 193 | 24 | 250 | 14 | F07 |

| 150 | 6" | 59 | 185.4 | 208.4 | 145 | 209 | 24 | 302 | 14 | F07 |

| 200 | 8" | 64.5 | 235.2 | 262.3 | 170 | 251 | 30 | 360 | 17 | F10 |

Advantages

1. Valve body casting precision, materials in line with standards, beautiful appearance, no grit, material inspection guarantee.

2. The valve seat rubber adopts EPDM rubber of the first-line brand in accordance with the standard. The elasticity and tension of the valve seat are more stable and reliable.

3. The valve body and valve plate are made of QT450-10 material, with spheroidization rate of more than 3 levels, tensile strength of 450Mpa and elongation rate of more than 10%.

4. The surface of the valve body adopts electrostatic powder thermal spraying technology, which is more environmentally friendly and weather-resistant, and ensures that the valve body will not change color for 36 months.

5. Each product is pressure tested by POPU's intelligent testing equipment and test report is generated automatically. All data and reports are kept for 5 years to ensure the factory pass rate.

6. Each product is packed with heat shrink film and built-in desiccant to isolate the dust in the air, which is easy to store and avoid moisture corrosion.