Intro

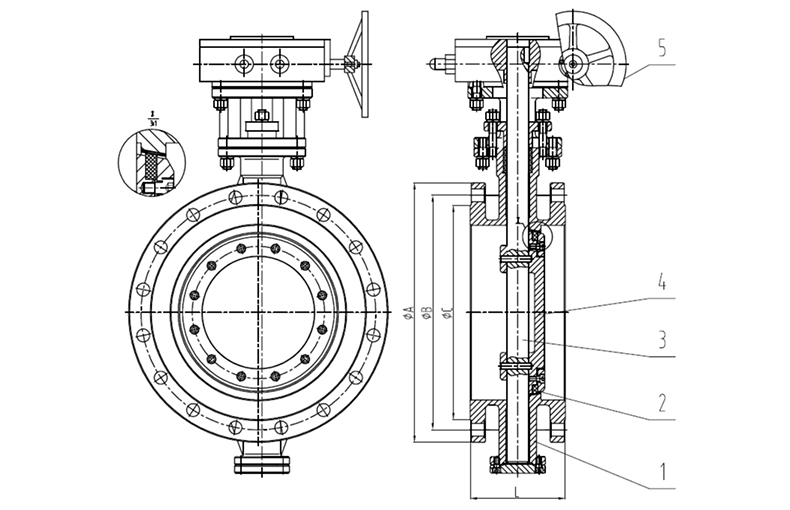

D343W-16P stainless steel flange three-eccentric butterfly valve is a long-life, energy-saving butterfly valve product. The product performance is at the leading level at home and abroad, high temperature and corrosion resistance, widely used in industrial pipelines such as power, petroleum, chemical, metallurgy, municipal construction, etc. to cut off or adjust the flow of media. This product adopts the three-dimensional eccentric principle design, and the valve seat adopts a multi-level structure compatible with hard and soft seals, with exquisite processing and advanced technology.

Parameters

| Size | length | PN10 | PN16 |

| DN | NPS(inch) | L | ΦA | ΦB | ΦC | ΦA | ΦB | ΦC |

| 50 | 2'' | 108 | 165 | 125 | 102 | 165 | 125 | 102 |

| 65 | 2 1/2'' | 112 | 185 | 145 | 122 | 185 | 145 | 122 |

| 80 | 3'' | 114 | 200 | 160 | 138 | 200 | 160 | 138 |

| 100 | 4'' | 127 | 220 | 180 | 158 | 220 | 180 | 158 |

| 125 | 5'' | 140 | 250 | 210 | 188 | 250 | 210 | 188 |

| 150 | 6'' | 140 | 285 | 240 | 212 | 285 | 240 | 212 |

| 200 | 8'' | 152 | 340 | 295 | 268 | 340 | 295 | 268 |

| 250 | 10'' | 165 | 395 | 350 | 320 | 405 | 355 | 320 |

| 300 | 12'' | 178 | 445 | 400 | 370 | 460 | 410 | 378 |

| 350 | 14'' | 190 | 505 | 460 | 430 | 520 | 470 | 438 |

| 400 | 16'' | 216 | 565 | 515 | 482 | 580 | 525 | 490 |

| 450 | 18'' | 222 | 615 | 565 | 532 | 640 | 585 | 550 |

| 500 | 20'' | 229 | 670 | 620 | 585 | 715 | 650 | 610 |

| 600 | 24'' | 267 | 780 | 725 | 685 | 840 | 770 | 725 |

| 700 | 28'' | 292 | 895 | 840 | 800 | 910 | 840 | 795 |

| 800 | 32'' | 318 | 1015 | 950 | 905 | 1025 | 950 | 900 |

| 900 | 36'' | 330 | 1115 | 1050 | 1005 | 1125 | 1050 | 1000 |

| 1000 | 40'' | 410 | 1230 | 1160 | 1110 | 1255 | 1170 | 1115 |

| 1200 | 48'' | 470 | 1455 | 1380 | 1330 | 1485 | 1390 | 1330 |

| 1400 | 56'' | 530 | 1675 | 1590 | 1535 | 1685 | 1590 | 1530 |

Advantages

1. All valve bodies are precision cast valve bodies, with qualified materials, fine appearance and no sand holes

2. The butterfly plate is processed by CNC lathe, and the sealing ring is a soft and hard multi-layer stacked metal ring, which has the dual advantages of metal and elastic sealing, ensuring excellent sealing performance in high and low temperature environments

3. The valve stem is made of stainless steel, and the strength of the valve stem is doubled after quenching and tempering, which reduces the opening and closing and leakage problems caused by valve stem deformation

4. After the product is pressed and debugged, the turbine adjustment screw is processed again, and the left and right lengths are adjusted to be consistent before delivery. The turbine adjustment screw of each product is equipped with a protective nut to protect the adjustment screw from damage

5. The valve plate is thick, the valve stem is thick, the pin is thick, and the valve seat is finely processed, flat, and has no welding scars

6. From the blank to the finished product packaging, every link is inspected at every level.